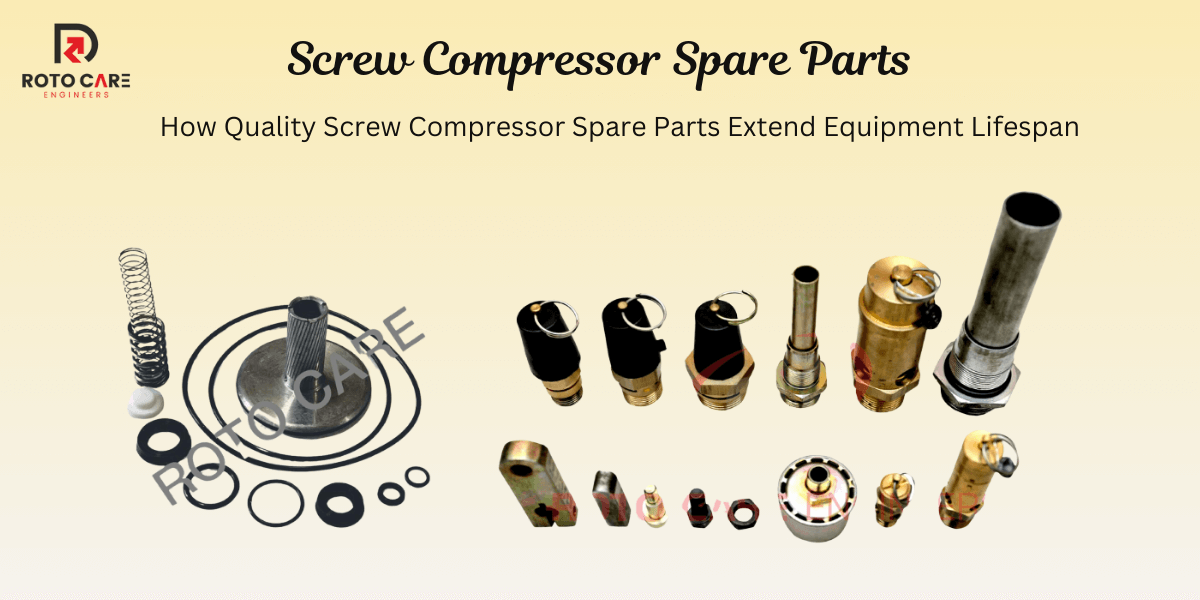

How Quality Screw Compressor Spare Parts Extend Equipment Lifespan

Industrial operations rely heavily on high-performing machinery to maintain productivity and reduce downtime. Among the vital components in many industries are rotary systems designed to compress air or gas efficiently. These machines, when coupled with high-quality replacement components, ensure uninterrupted performance and long-term reliability. Investing in Screw Compressor Spare Parts is critical to maintaining the equipment’s lifespan and operational efficiency.

Importance of High-Quality Components in Maintenance

Over time, even the most robust industrial equipment experiences wear and tear due to continuous usage. This natural degradation makes it essential to use premium-grade replacement components. Low-quality replacements often fail prematurely, leading to frequent repairs and unexpected downtime. By choosing dependable alternatives, businesses can significantly reduce operational interruptions, which translates to improved productivity and cost savings.

High-quality replacements are specifically designed to fit and function seamlessly with the original machinery, maintaining optimal performance. These components are built with superior materials and undergo stringent quality checks to ensure they can handle extreme operating conditions, such as high temperatures and pressure.

Enhanced Performance Through Precision Engineering

Precision-engineered replacements not only extend the life of industrial equipment but also enhance its performance. When manufacturers design replacements, they account for factors like material compatibility, thermal expansion, and resistance to wear. This attention to detail ensures that the machinery operates at its best, minimizing energy losses and maximizing output.

Additionally, reliable replacements help maintain the structural integrity of critical components, preventing damage to interconnected systems. For example, when the right rotor is installed, it ensures balanced operation and reduces vibrations, which could otherwise lead to mechanical failures.

Cost-Effectiveness in the Long Run

While high-quality replacements may come at a higher initial cost, their long-term benefits far outweigh the expense. Cheap alternatives often result in frequent repairs, higher energy consumption, and decreased productivity. By contrast, durable replacements require fewer interventions, thus saving money on maintenance and replacement costs.

Investing in premium replacement components also lowers the likelihood of catastrophic failures, which can be financially draining and disrupt operations. Moreover, these components help maintain the machine’s energy efficiency, further reducing operational costs.

Utilizing Genuine Screw Compressor Parts

When it comes to maintaining rotary systems, opting for genuine replacements is essential. Authentic parts ensure compatibility and maintain the equipment’s performance standards as per the manufacturer’s specifications. Using non-genuine alternatives may result in subpar operation, leading to potential safety hazards and voided warranties.

Quality replacements contribute to smoother operation by maintaining consistent air or gas compression levels. This reliability is crucial in industries like manufacturing, where uninterrupted airflow is essential for production. Additionally, these components prevent excessive wear on related parts, ensuring the system operates harmoniously.

Role of Regular Maintenance in Extending Equipment Lifespan

Regular maintenance plays a pivotal role in the longevity of industrial equipment. By conducting timely inspections and replacing worn-out components, businesses can prevent minor issues from escalating into major problems. Quality replacements, combined with a comprehensive maintenance plan, ensure the equipment remains in optimal condition for years.

Preventive maintenance involves monitoring critical parameters like temperature, pressure, and lubrication levels. Addressing any irregularities early can significantly reduce stress on the machinery. Coupling this with high-grade replacement components ensures uninterrupted performance and a prolonged lifespan.

Environmental and Safety Benefits

Beyond operational and cost advantages, quality replacements also contribute to environmental sustainability. Well-maintained equipment consumes less energy, thereby reducing its carbon footprint. Additionally, using reliable replacements minimizes the risk of hazardous leaks or emissions, promoting workplace safety and compliance with environmental regulations.

In industries where safety is paramount, such as chemical processing or oil and gas, durable components are indispensable. They reduce the risk of accidents caused by equipment failure, ensuring a safe working environment for employees.

The Impact of Screw Compressor Spare Parts on Operational Efficiency

The longevity of industrial equipment is directly tied to the quality of its components. Screw Compressor Spare Parts ensure that rotary systems remain efficient, reliable, and durable. By prioritizing genuine and high-grade replacements, businesses can optimize performance, reduce downtime, and achieve significant cost savings.

Conclusion

Investing in high-quality components is an investment in the long-term reliability and efficiency of industrial equipment. Reliable replacements not only improve performance but also prevent costly repairs and downtime. With the right approach to maintenance and by utilizing Screw Compressor Parts, businesses can maximize their equipment’s operational lifespan. By ensuring seamless integration and enhanced durability, these components remain a cornerstone of industrial success.